With improved insights about supplier performance, your team can ensure that they are engaging with financially stable suppliers capable of meeting order requirements and your customer's expectations.

How to Improve Supply Chain Visibility

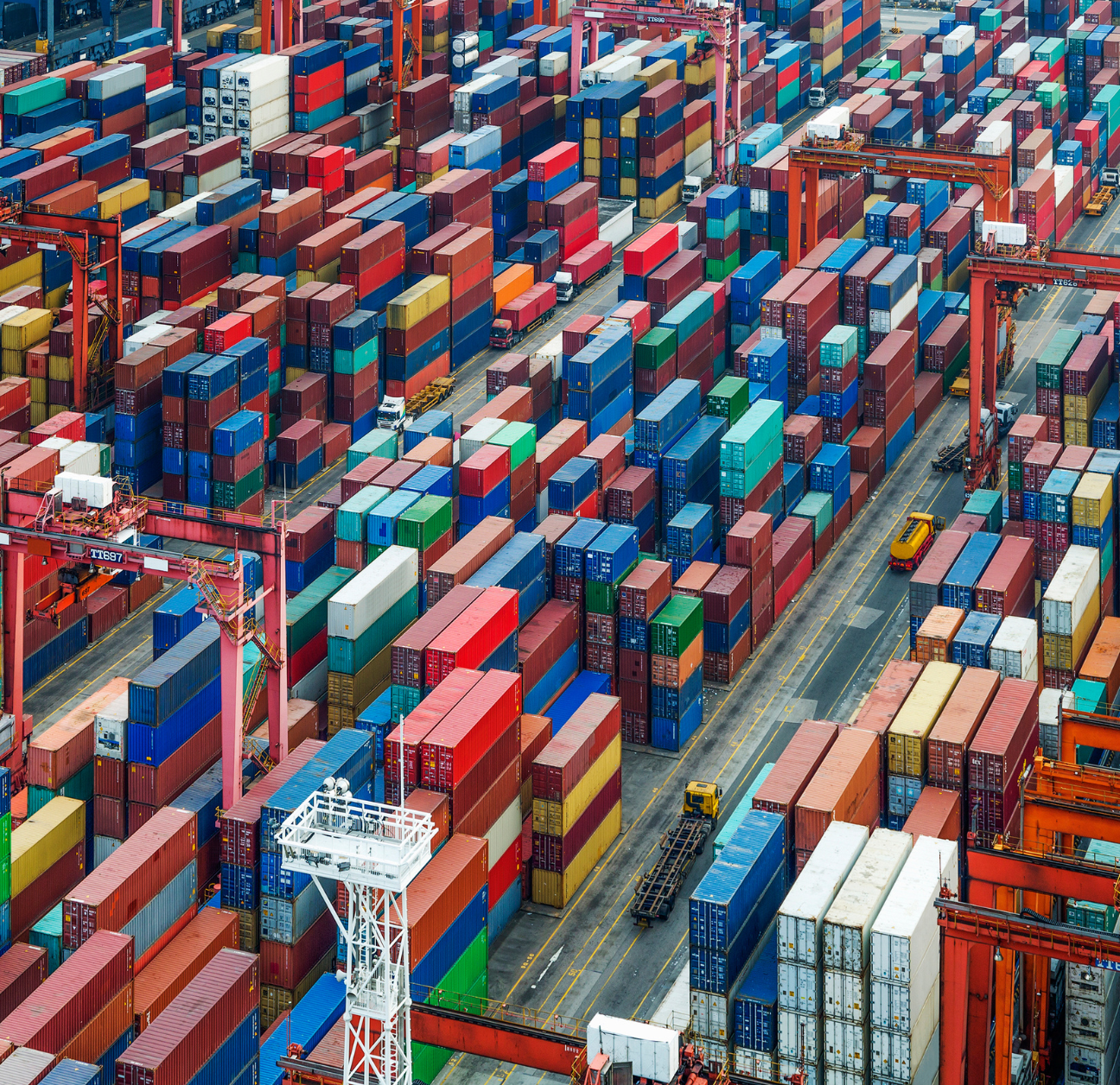

Companies of all sizes are exploring how to improve supply chain visibility in the coming years, especially in the wake of widespread disruptions in the supply chain caused by the COVID-19 pandemic.

While many businesses have become accustomed to navigating supply shocks caused by severe weather or other unexpected supply shortages, the COVID-19 pandemic revealed vulnerabilities unlike the impact of many previous events. Amid shutdowns and uncertainty globally, companies suddenly were faced with trade restrictions, factory shutdowns, product shortages, escalating freight rates, increased demand, and a sudden dependency on “just-in-time” inventory systems.

As a result, many companies are accelerating investments in advanced technology and solutions to improve supply chain visibility.

What is supply chain visibility?

When individuals in various industries mention supply chain visibility, they are referring to the enhanced ability to track different products at various stages of transit. A supply chain visibility platform provides users with a clear view of the inventory and activity.

As a result, shippers using supply chain visibility software can enhance customer service by providing real-time updates on the status of shipments. Also, others engaged in the supply chain can better manage costs, minimize risks, and better anticipate and navigate disruptions.

With improved supply chain visibility, employees can become more agile with inventory control and have better information about the transit of products. With additional real-time data insights, they are able to make informed critical decisions in advance.

When paired with other processes, such as S&OP, supply chain visibility platforms can ensure that companies are further optimizing supply chains.

What is S&OP?

S&OP is short for sales & operations planning, is a process that ensures that a manufacturer’s supply is matching demand. By eliminating departmental silos, a company can ensure that the sales department is actively collaborating with operations on a production plan.

A sales and operations planning example that is highly efficient includes other departments that are involved in the demand and supply aspects of the corporation. These departments can include procurement, marketing, transportation, finance, procurement, and manufacturing.

S&OP varies from company to company, but typically includes several areas for collaboration, including a review of data such as sales and anticipated inventory; demand planning that considers factors like forecasted demand; production planning; and reconciliation.

While S&OP refers to a process which has been implemented at many companies since the 1980s, S&OP software has significantly streamlined the process through automation. Through an S&OP platform, representatives from various departments can readily access relevant data and analytics.

With S&OP, teams can enhance the accuracy of forecasts, make informed decisions about inventory, and as a result, save on inventory expenses. Increased efficiencies throughout operations allows companies to spend more time on customer success and innovation.

Lack of Visibility in Supply Chain

With supply chains becoming increasingly global and complex, a lack of visibility in the supply chain can result in significant consequences for shippers and forwarders alike. Many enterprises have stressed the importance of supply chain visibility in recent years. However, with companies of all sizes engaging with suppliers worldwide, smaller companies, and even logistics service providers, are also embracing supply chain visibility solutions to address challenges in their supply chains.

Without supply chain visibility software, companies risk exposing themselves to numerous vulnerabilities, including losing track of their shipments or customer's goods, inventory shortages, and dissatisfied customers.

As a supply chain visibility example, consider some of the challenges facing a manufacturing company that is operating with limited insights into their supply chain.

Without a transparent view about where inventory is at any given time, a team may be unaware of potential risks caused by adverse weather conditions, including hurricanes and wildfires, major events, or labor disputes. They may also find it difficult to navigate challenges that emerge because of interruptions that make it difficult to forecast demand, bad data that misinforms decision-makers, and reliance on suppliers that fail to deliver to their expectations.

Supply chain visibility data can lead to the following benefits:

Better management of suppliers: With improved insights about supplier performance, teams can ensure that they are engaging with financially stable suppliers capable of meeting order requirements and other expectations.

Minimize the impact of disruptions: With enhanced data insights about potential disruptive events, teams can develop advanced plans that help them navigate or steer clear of disruptions.

Deliver on customer expectations: Enhanced visibility into the supply chain in real time provides companies with the opportunity to keep their customers updated on delivery times. It also ensures that businesses are nimble in seeking out other solutions on their customers’ behalf in the event of a delay or a problem with a supplier.

Make data-driven decisions: With more accurate, real-time data provided through supply chain visibility platforms, companies can ensure that they are making solid decisions and identifying potential risks in the chain.

Improving the Visibility of Demand

Improving the visibility of demand in a company's supply chain can also help companies attract new customers and enhance customer retention. With increasingly demanding customers, companies are now faced with the expectation to keep them regularly informed about updates on their shipments.

Visibility in logistics can help teams minimize the impact of disruptions and identify challenges and opportunities that can positively influence supply chain lead time.

Company leaders trying to understand how to improve supply chain visibility and the resulting efficiencies they can gain, may want to consider customer satisfaction as another key benefit.

Many customers of logistics service providers have changed their expectations about delivery tracking capabilities, fueled in part by extreme transparency into their shipments as consumers. Just like in their personal lives, shippers expect to know exactly where their goods are and when they are expected to arrive so they can make better decisions.

Continuous communication from a logistics service provider to their customer through automated updates can foster a sense of reliability.

Real Time Supply Chain Visibility

Real-time supply chain visibility has become essential in the manufacturing and delivery of products. Real-time visibility meaning can be defined as the logistics activities that track the movement of packages in real time as they make their way from suppliers, manufacturers, and warehouses to the customer.

Supply chain visibility solutions operate with GPS-tracking devices and other advanced software that enables company leaders to plan, schedule, and monitor the company’s logistics process at various stages. The items that can be tracked include the delivery of raw materials, regulatory details, and shipping data from ocean liners, trucks, rails, and aircraft. As a result, businesses can realize gain numerous advantages, including the streamlining of operations, the reduction of lead times, better customer service, and better internal communications.

Because of these supply chain visibility benefits, the supply chain visibility market size has significantly grown in recent years. According to the report "Supply Chain Management Software Market by Deployment, Application, and Geography - Forecast and Analysis," the supply chain software market experienced a year-over-year growth of 7.23 percent in 2021 at a CAGR of 11 percent.

The market is projected to continue to grow, reaching $52,632.37 million by 2030.

How Does Improved Supply Chain Visibility Improve the Planning Process?

A well-managed supply chain is critical to sustaining a successful business while also satisfying all stakeholders. To achieve optimal results, company leaders must invest in supply chain visibility solutions that are effective in addressing the needs of all tiers of the supply chain.

To assess various solutions, they must understand how supply chain visibility helps plan and forecast activities at various points of the supply chain. Some questions to consider include:

How does improved supply chain visibility improve the planning process?

What is the importance of planning and forecasting in supply chain management?

The answers can vary depending upon the industry and company, but some practices can be universal in gaining efficiencies throughout the supply chain. Here are some ways that teams can favorably act on data insights into the end-to-end supply chain process.

Prioritize diverse suppliers. Teams can more readily identify and remove unreliable suppliers from their rosters and find better alternatives when looking at smaller organizations or more diverse options. Through automation that provides supply chain visibility, companies can compare costs and assess on-time and late delivery times. As a result, by improving the quality of suppliers on its roster, company can reduce its lead time.

Enhance collaboration among partners. By providing insights into demand visibility supply chain to suppliers and other partners, companies can ensure that they are prepared to handle variations in the sizes of orders.

Automate workflows. By automating their order processing workflows, companies can address problems with internal communications, getting customer purchase orders processed, and minimize the risks associated with lost orders.

How Can You Reduce the Lead Time of a Supply Chain Process?

With customers demanding faster shipments, it’s critical for companies explore solutions on how to reduce lead time in manufacturing, as well as how to reduce lead time in software development. Gains in efficiency at different phases can result in a quicker turnaround time that leads to quicker deliveries.

How can you reduce the lead time of a supply chain process? Through the insights provided by supply chain visibility software, a company can reduce lead time by identifying areas to increase efficiencies, anticipating disruptions that can delay shipments, and ensuring compliance in a timely manner.

Access to real-time information provided by a supply chain visibility platform can ensure that company leaders are informed with insights that allow them to make decisions to minimize the impact of disruptions or to take advantage of opportunities to get the final product to customers.